How to Choose the Right Waste Water Pump for Your Needs?

Choosing the right waste water pump can be a challenging task. With numerous options available, making an informed decision is crucial. According to a report from the Global Water Pump Market, the waste water pump sector is expected to grow significantly, reaching an estimated $9.4 billion by 2025. This data highlights the increasing importance of efficient waste water management.

Expert John Smith, a renowned figure in the waste water industry, states, "Selecting the appropriate waste water pump can enhance system performance and reduce operational costs." His insight emphasizes the importance of considering various factors such as pump type, flow rate, and efficiency ratings.

Many users often overlook specific requirements. For instance, the pump's material could impact longevity. While some pumps are designed for light-duty tasks, others cater to more severe applications. Ensuring compatibility with waste type is vital. Users should also reflect on their unique needs to avoid potential failures. Even seasoned professionals can find themselves puzzled by their options.

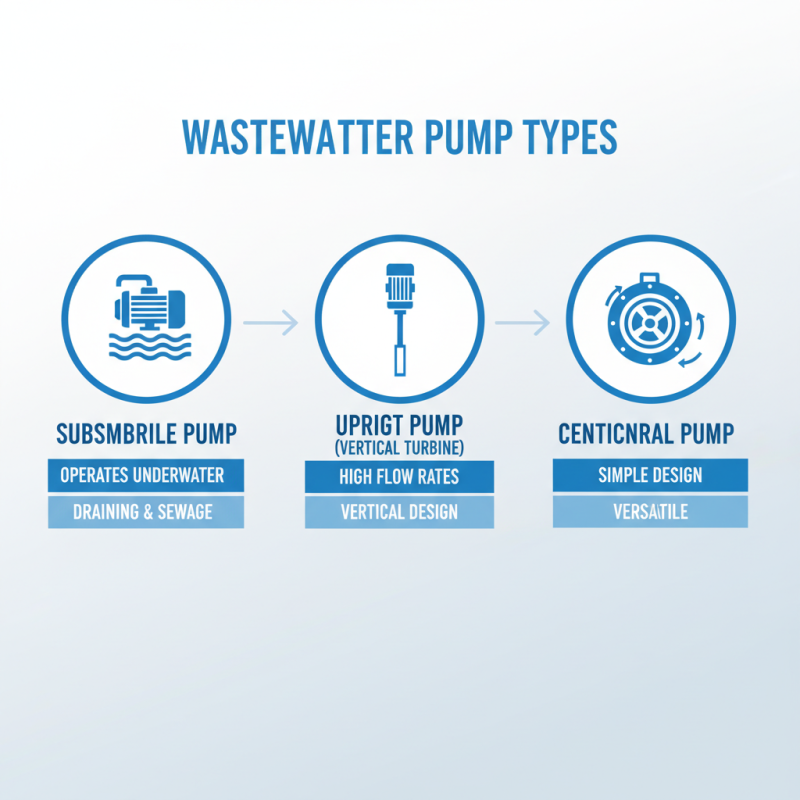

Understanding the Different Types of Waste Water Pumps Available

When selecting a waste water pump, understanding the different types available is crucial. There are several main types to consider: submersible pumps, upright pumps, and centrifugal pumps. Submersible pumps are designed to operate underwater. They are efficient for draining and sewage applications. Upright pumps, also known as vertical turbine pumps, are great for high flow rates. Centrifugal pumps are favored for their simple design and versatility.

Tips: Assess your specific requirements before choosing. Think about the volume of waste water and the pump's location. A submersible pump may be ideal for tight spaces. Make sure the pump can handle solids if necessary. Remember to check the power source too.

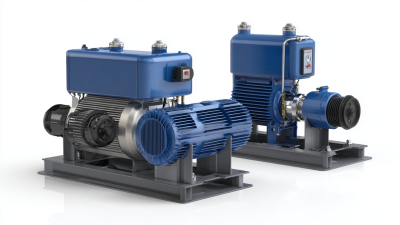

Different environments call for different solutions. A residential setting may require a smaller pump, whereas industrial needs can demand larger, more powerful options. Don't forget to factor in maintenance needs. Some pumps require more attention, which can be a hassle. You should also ask yourself if the initial cost is worth it long-term.

Key Factors to Consider When Selecting a Waste Water Pump

Choosing the right waste water pump involves several critical factors. One of the most important aspects is the pump capacity. You need a unit that can handle the flow rate your application requires. Understand the volume of water you typically deal with. If you underestimate this, your pump may fail to perform adequately, leading to potential issues.

Another key factor to consider is the type of waste water you will be pumping. Different pumps are designed for specific materials. For instance, solids content in the water can greatly influence your choice. If you're pumping sewage, a robust, capable pump is necessary. This calculation isn't always straightforward and requires careful thought.

Additionally, consider the pump's energy efficiency. An efficient pump saves money in the long run. Be mindful that some pumps may have a higher purchase price but could lead to significant savings over time. Reflect on your long-term usage patterns. Ultimately, choosing a waste water pump is not just about immediate needs but also future demands.

Assessing Flow Rate and Head Requirements for Your Application

Choosing the right wastewater pump involves understanding your specific requirements. One key factor is flow rate. This refers to how much fluid the pump can move over time. You need a pump that fits your system's flow demands. Measure the volume of wastewater generated daily. This number tells you the minimum flow rate needed.

Next, consider head requirements. The head is the height that the pump needs to lift the wastewater. Different applications have different head requirements. Calculate the vertical distance from the wastewater source to the discharge point. Don't forget to include any friction losses from pipes and fittings. This ensures the pump can handle the load.

**Tips:** Always check the manufacturer’s specifications for flow and head ratings. Consider using a pump with a slightly higher capacity than needed. This provides a buffer for unexpected increases in flow or head. Additionally, if your setup is complex, consulting an expert could save you time and hassle. It’s worth it to avoid common pitfalls.

Comparison of Waste Water Pump Flow Rate and Head Requirements

Evaluating Material Durability and Maintenance Needs for Pumps

When selecting a waste water pump, material durability is crucial. Pumps often face harsh environments, including corrosive substances and high temperatures.

Common materials are stainless steel, cast iron, and thermoplastics. Each has unique strengths and weaknesses.

Stainless steel resists corrosion well but may be more expensive.

Cast iron is durable yet can rust if not maintained properly.

Maintenance needs also vary greatly based on the pump's materials. Stainless steel pumps typically require less frequent checks due to their robust nature.

However, cast iron pumps could need regular inspections for rust and sediment buildup.

Thermoplastic pumps can be lighter, but they might wear out faster under stress.

Remember to evaluate your situation. Know the chemical compositions you'll handle.

Consider the pump's operating environment.

Regular maintenance can help prolong a pump's lifespan. Ignoring wear and tear might lead to costly breakdowns.

Planned inspections can save time and money.

Reflect on your needs and the environment your pump will face. Choose wisely, as the right material can significantly impact performance and longevity.

Exploring Cost vs. Performance Trade-offs in Pump Selection

When selecting a wastewater pump, cost and performance are key considerations. A recent industry report highlighted that approximately 30% of operational costs come from energy consumption. This means that a cheaper pump may not be the best choice if it runs inefficiently. For instance, high-efficiency pumps can save up to 20% on energy costs. However, they often come with a higher initial price tag.

You often need to consider the specific requirements of your project. A pump that handles high solids content will differ from one designed for clear water. The right choice can extend the pump's life, while an ill-suited model can lead to frequent breakdowns.

Pump downtime can result in costly repairs and increased maintenance.

Budget constraints are real. Sometimes the savings from a less expensive pump seem appealing. Yet, this might lead to higher long-term costs due to inefficiency and maintenance needs. A mid-range pump could provide the perfect balance between cost and performance. Reflecting on these trade-offs is crucial for anyone involved in wastewater management.

Related Posts

-

How to Choose the Right Waste Water Pump for Your Home or Business

-

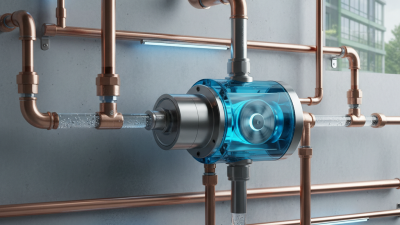

Why You Should Choose an Inline Water Pump for Efficient Water Circulation

-

Top 10 Dirty Water Pumps: Efficient Solutions for Heavy-Duty Water Removal in 2023

-

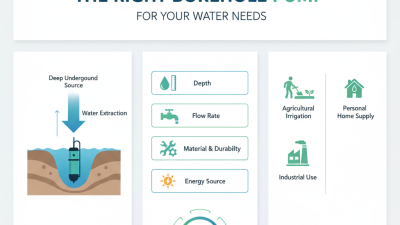

How to Choose the Right Borehole Pump for Your Water Needs

-

Why Choose a PTO Water Pump for Your Irrigation Needs?

-

The Essential Guide to Choosing the Right Submersible Pump for Your Needs